7-1 Abstract

Through the rapid development of communication technology in recent years, the unmanned aerial vehicle (UAV, as called drone) has gradually matured. Power Supply Department of TPC tried to use drone to assist the inspection work, and successfully found the fault location of the tower on the river bed. As the technology became more mature, the works of the tower foundation monitoring, line inspection, finding fault location, and tower corrosion investigation are implemented. Especially the extreme climatic in recent year, there’s more nature disasters. After wind, rainstorms or road landslides, vehicles could not be reached, so the location of faults on transmission line were found with assistance of drones. In addition, the types of occupational disasters for overhead transmission line operations are mainly “falling” and “inductive”. With the assistance of the drones, this type of disasters can also be reduced.

7-2 Smart Inspection

Most of Taiwan’s overhead transmission line towers are located on the middle of high mountains or river catchment areas. Traditional inspections mostly rely on manpower. Currently, TPC is actively promoting the transformation of UAV smart inspections and commissioned Microsoft Corporation to develop an AI image recognition system, combined with UAVs to do the work. Smart inspection can improve the visual blind spots of traditional manpower limited by terrain and environment in one fell swoop, and improve inspection efficiency.

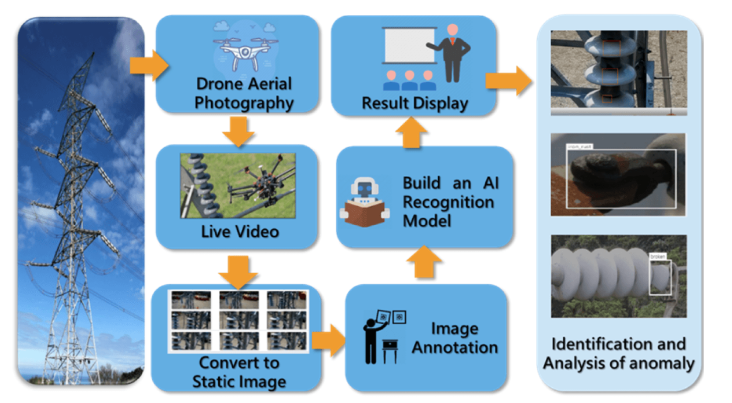

After carrying out drone aerial photography through a licensed pilot, the video of the fault location will be sent back to the cloud for data processing. The professionals will perform manual annotation and model training for abnormalities such as obstacle flashover, damage, and iron corrosion, and establish artificial intelligence abnormalities image recognition model. It will be used to assist in the abnormal detection of related transmission equipment. (Fig. 1) It effectively improves the efficiency of transmission line operation and maintenance, and improves the stability and reliability of the power system.

Figure 1. AI Image Recognition System for Equipment of Transmission System

7-3 Conclusion

Due to the rapid development of information in recent years, the transmission of messages requires fast and accuracy. Traditional line inspection is often limited by terrain, environment factor etc. By the assistant of drones for line inspection, the efficiency and effectiveness of inspection can be improved, also it can improve the quality of inspections.

“Smart inspection” is the future and ongoing type of transmission line inspection. The complete fleet management and operation manpower training establishes the foundation. New technologies are successively introduced to make the inspections more accurate and reliable, and the weaknesses can be detected efficiently to improve stability of power supply.