Supply Reliability Index

-

1-1 Abstract

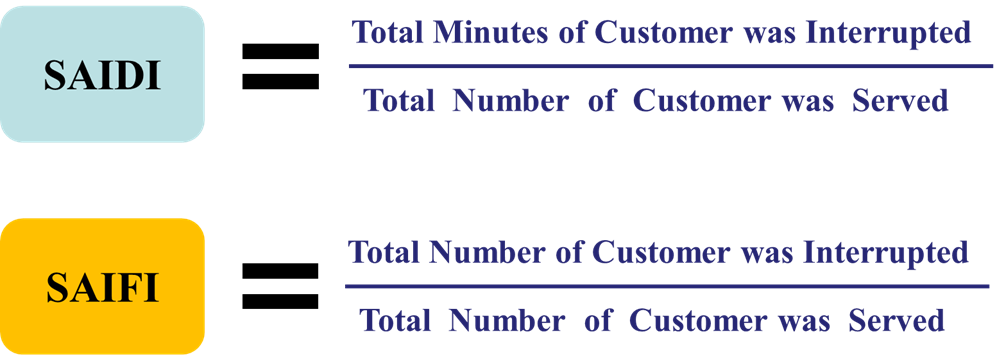

Taipower company adopts the System Average Interruption Duration Index (SAIDI) and the System Average Interruption Frequency Index (SAIFI), which are commonly used in the international power industry. It is in compliance with IEEE 1366 std and the World Bank for SAIDI and SAIFI measures basic conditions.

-

SAIDI (min / household•year)

The System Average Interruption Duration Index (SAIDI) indicates the total duration of interruption for the average customer during a predefined period of time. It is commonly measured in minutes or hours of interruption.

-

SAIFI (times / household•year)

The System Average Interruption Frequency Index (SAIFI) indicates how often the average customer experiences a sustained interruption over a predefined period of time.

-

SAIDI (min / household•year)

-

1-2 The Components of Power Supply Reliability

-

Planned Outage

In recent years, the actual planned outage time accounts for about 70%~76% of the company's average power outage time.

-

Forced outage

In recent years, no warning accidents, force outages time accounts for about 24%~30% of the Taipower's average power outage time.

-

Planned Outage

-

1-3 Conclusion

-

If the customer interruptions is more than 1 minute, it will be counted in the statistics for SAIDI & SAIFI in Taipower company; however, if the time of customer interruption is more than 5 or 3 minutes, that will be counted in the statistics in most power companies. Thus, the requirements for reliability in Taipower is more stringent for current power companies standard.

SAIDI performance in the past 10 years

YEAR 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 SAIDI 16.268 16.274 16.898

(32.572)*116.187 16.488 15.931 16.376

(43.516)*214.936

(91.285)*315.225 15.831 Planned

Outage12.321 12.223 12.355 12.052 12.125 11.696 11.732 11.298 11.292 11.325 Forced

Outage3.947 4.051 4.543 4.135 4.363 4.235 4.644 3.638 3.933 4.506 SAIFI performance in the past 10 years

YEAR 2015 2016 2017 2018 2019 2020 2021 2022 2023 2024 SAIFI 0.220 0.208 0.212

(0.553)*10.227 0.209 0.230 0.233

(0.864)*20.181

(0.467)*0.186 0.209 Planned

Outage0.058 0.058 0.057 0.057 0.059 0.059 0.059 0.057 0.056 0.055 Forced

Outage0.162 0.150 0.155 0.170 0.150 0.171 0.174 0.124 0.130 0.154 -

*1:A major power outage occurred on August 15, 2017. The main reason was the gas supply interruption of CPC Corporation, Taiwan. The SAIDI and SAIFI values caused by this accident were 32.572 (mins/household.year) and 0.553 (times/household.year) respectively

*2:A major power outage occurred on May 13 and May 17, 2021. The SAIDI and SAIFI values caused by this accident were 43.516 (mins/household.year) and 0.864 (times/household.year) respectively.

*3:A major power outage occurred on March 3, 2022. The SAIDI and SAIFI values caused by this accident were 91.285 (mins/household.year) and 0.467 (times/household.year) respectively.

Taiwan Electricity Trading Development

Taiwan power company (hereinafter referred to as “TPC”) has made it a priority to enhance the flexibility and resilience of the grid in order to achieve net-zero emissions. Firstly, in 2019, TPC launched Non-Conventional Power Resources Participating Ancillary Services on Electricity (NCPRS), a program for end-user to reduce load or use their own electricity generation equipment. This program successfully attracted more than 84MW of resources to participate, and these resources can be used as a conventional generation unit to provide spinning reserve for the Central Dispatch and Control Center (CDCC). Along with the establishment of the market operator of TPC and with the participation of the international power industry, the average executive rate of ancillary service provided by these resources are over 106%. This result can be seemed as the achievement of the LAAR (Load as a resource) goal.

In addition, TPC has also planned how to use energy storage system (ESS). In collaboration with domestic enterprises and ESS manufacturers, TPC has initiated the "Asia's first" AFC project to procure 15MW ESS resources providing frequency regulation services. These AFC ESS resources can automatically follow the frequency variation and can adjust its output/input within 1 second. The functionality of AFC ESS resources has been proved during the blackout incident happened in 2021, which means that they have the capacity to prevent the power grid contingency.

Based on the success of the AFC project mentioned above, Taiwanese government has drafted a formal regulation conce

rning the “Energy Trading Platform” which instructed TPC to establish a " Energy Trading Platform "(ETP) in July 2021. Nowadays, along with the participation of the utility generation enterprise, TPC has successfully recruit dozens of enterprises to participate in the ETP. TPC also created the role of QSE which ask participants of ETP to pass the ETP Proficiency test, and there has been more than thousands of people passed this test. The capacity of resources which has registered to ETP has over than 170MW until the end of January 2022.

TPC expects also to create a new trading product in July 2022 for long-term ESS and expects to implement 1,000MW ESS in 2025. It is expected to provide smoothing and load-shifting services to the grid.

Along with the energy transition goal in 2025, it is expected to obtain more than 3,900MW power resources with various types through ETP. TPC also plans to further open the intraday imbalance energy market. With the participation of these dispatchable power resources, Taiwanese power grid can be one of the most sustainable and robust grids in the world, which can also bring greater confidence in the path to achieve net-zero emission goal.

(Currently, the types of decentralized power resources acquired include ESSs, electric vehicle charging stations, telecommunication equipment rooms, self-generating equipment, cogeneration, demand response from industrial or domestic users, etc.)

-

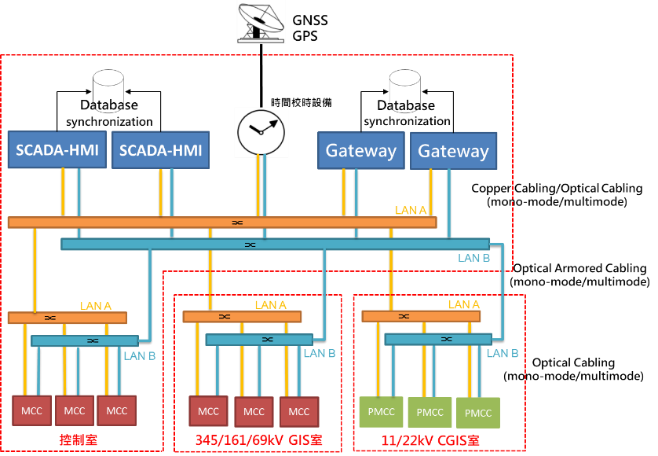

3. The building of IEC 61850

At present, nearly 90% of the substation automation monitoring architecture adopt remote terminal units (RTUs), and most of the power meters, IEDs and RTUs use communication protocol DNP3.0. The monitoring architecture of the other substations adopt Local SCADA and gateway. The communication protocols between the gateways and IEDs are different (Modbus, DNP, LON, Profibus, etc.). The main function of these two substation automation methods is updating the real-time operation information in substation to the control center for dispatching (vertical communication), while the information cannot be exchanged horizontally between substations.

The full name of the IEC 61850 standard is "Communication networks and systems for power utility automation." The latest version, Edition 2, is an internationally accepted power automation standard that conforms to the future development trend of smart grids. Its main purpose is to provide the interoperability between different brands of IEDs.

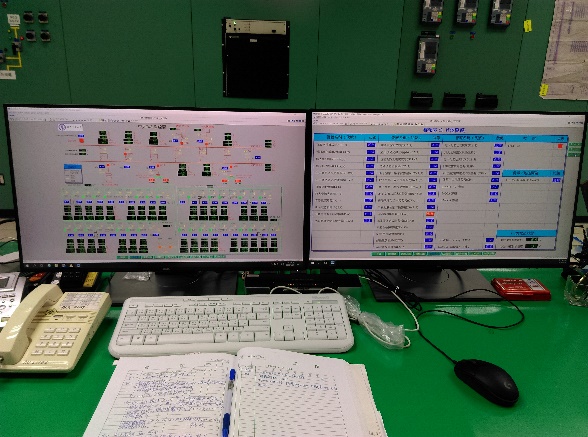

Figure 1. SCADA-HMI

Figure 2. Switch and gateway

In addition, the substation automation following the IEC 61850 monitoring architecture (shown as Figures 1 to 4) is also beneficial for the improvement of the reliability of power supply. This architecture provides a platform for horizontal communication (GOOSE) of automated equipment in the substation (shown as Figure 5), enabling various equipment that enables to complete the application scenario of protection and operation in power system.

Figure 3、4. MCC and PMCC IED

Figure 5 The architecture of IEC 61850

-

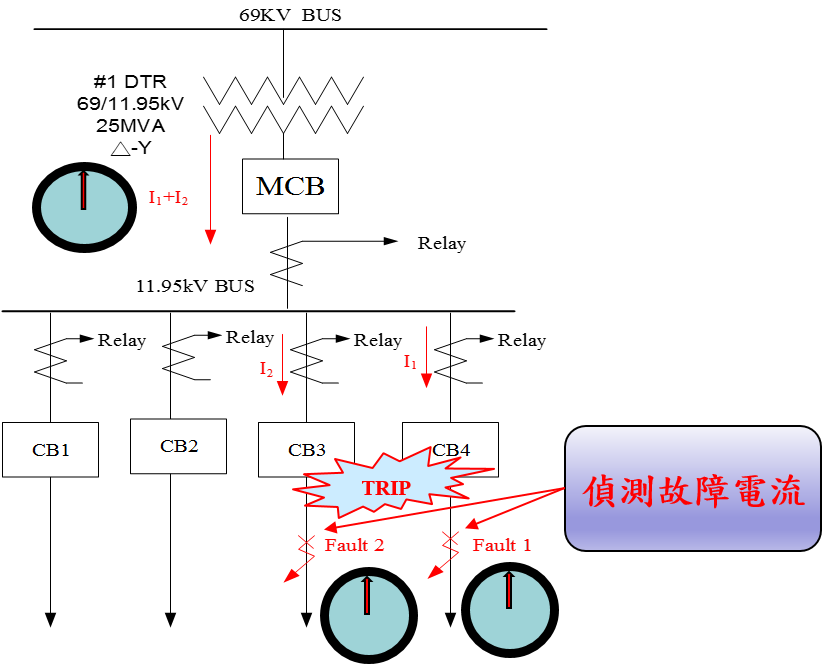

3.1. GOOSE Application of Simultaneous Accidents between Two Feeder Lines in compliant with IEC61850 Substation

-

A. Abstract

The application of smart grids in the field of power transmission and transformation is mainly on the construction of substation automation based on the internationally accepted IEC 61850 standard. Intelligent electronic devices (IED) are the basic elements of digital automation substations, providing the protection, measurement, control and communication functions required by the system, and the GOOSE function which transmit events fast is used to transmit important instantaneous command signals between multiple IEDs. For this reason, the digital network communication is the substitute for the hard-wired control loop between traditional devices to achieve IEDs interoperability. In order to solve the problem of protection coordination difficulty caused by the simultaneous failure of the common feeders, which caused cross-zone tripping, the GOOSE information can be used to detect the IED trip protection logic to speed up feeder tripping, which strengthen the protection coordination between upstream IEDs and downstream IEDs, speed up the IED tripping on fault feeder to isolate the fault and reduce the scope of power failure.

-

B. Construction

Taking the 11.95kV BUS devices in Figure 6 as an example, there are MCB, CB1, CB2, CB3, and CB4, five circuit breakers. Among them, the CB1, CB2, CB3, and CB4 are feeder circuit breakers, and their IEDs planning GOOSE command accelerates CB tripping.

Figure 6

-

Logical summary description:

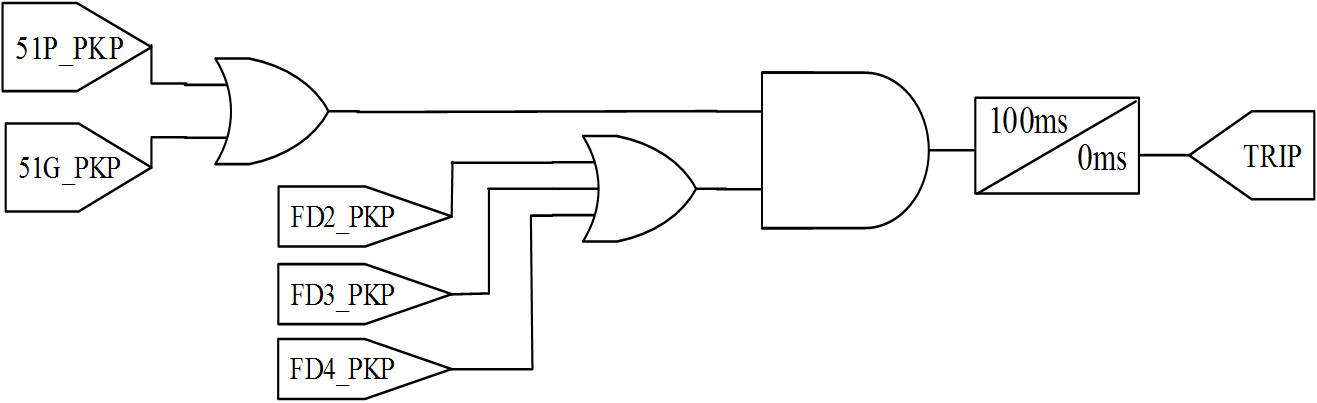

When any two feeders have a fault current at the same time, the two feeders will speed up immediately after judging the 6-cycle stable delay (you don't need to wait for the 51 / 51N relay delay-end and tripping). It can avoid simultaneous failure of the two feeders’ fault current smaller than the fault situation of a single feeder that makes 51 / 51N relay take a long time to operate, which causes the MCB's 51 / 51N action to trip. The relevant logic plan is as follows:

-

Accelerated trip logic:

Once a fault occurs on the CB1 feeder, when the 51 / 51N relay pickup and the IED have received the pickup Goose signal from other feeders in the same bank, if more than two feeders fail at the same time, a large current will be generated in MAIN, causing MAIN's IED to start tripping, causing incorrect trips and expanding power outages.

In order to prevent this phenomenon, when two or more feeders fail at the same time, we use the GOOSE on the IEDs of each feeder to transfer the PKP to each IED on faulted feeder, determining that when the two feeders fail at the same time should be delayed and tripping after 6 cycles to prevent MAIN CB tripping due to large currents first, causing a power outage on the sound feeder.

-

Logical summary description:

-

C. Benefit analysis

When more than two feeders have fault occurred at the same time, we accelerate the accidental feeder trip to avoid the action of the main circuit breaker, reducing the scope of power outages and improve the efficiency of power supply.

-

A. Abstract

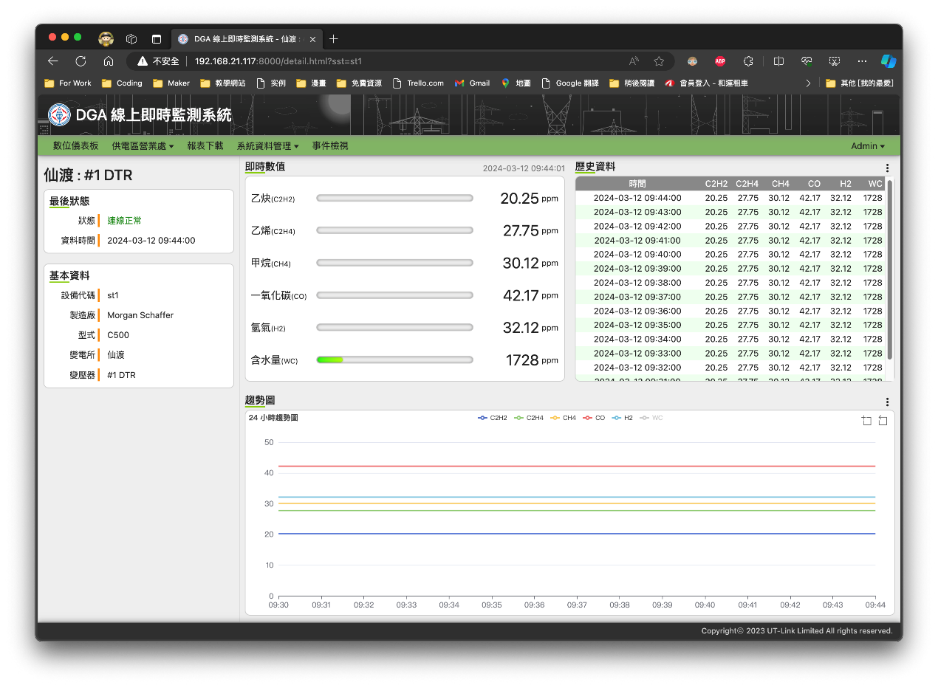

Base on power supply dispatch’s substation maintenance manual, TPRI’s oil test will be done every year unless fault or abnormal situation of transformer happens. It is impossible to know the internal fault situation of the transformer in advance if we cannot obtain the gas content of the oil in the transformer and the operating status of the equipment timely. Current DGA(Dissolved gas analysis, DGA) shows the total amount of gas, it is hard to know exactly the amount of each gas, and the high number of abnormalities and expensive maintenance makes it not economical.

To ensure the operation safety and prevent preventive maintenance, power supply dispatch must install DGA, current combustible gas detection device replaced from total type to component type. It can obtain the content of gas components (H2, CO, CH4, C2H2, C2H4, and water content) in the oil and alarm information, and judge the health of the internal operation of the transformer through each gas trend chart as the basis for CBM. It is expected that the effectiveness of the staff can be increase, equipment failure and blackout time can be decrease and ensure stable power supply.

You can see the abnormal status of the subordinate unit according to the authority.

Besides DGA, planning of existing transformer oil gas monitoring, transformer equipment asset management, and artificial intelligence AI applied to the transformer operation and maintenance strategy expert system for horizontal information integration and database interface to further master the transformer operation situation. If the abnormal situation of transformer is analyzed correctly, power outage maintenance can be arranged in time to avoid unforeseen power outages caused by accident.

-

5-1 Abstract:

Transmission towers are a vital element of the transmission system. However, natural environmental factors, such as wind and sun exposure, gradually corrode and damage tower structures over the years. Consequently, towers must periodically be replaced.

Old transmission towers are typically replaced in one of two common ways. In the first method, power is turned off in all transmission lines on the old tower. Lines are then switched to the new tower one by one. Unfortunately, this “power outage method” reduces system scheduling flexibility and increases operating risks. In the second method, temporary poles and lines are erected. This method requires additional land to accommodate temporary poles. It may be more difficult in some areas with poor land.

The "tower wrapping replacement method" proposed in this article solves the difficulties associated with both conventional replacement methods. It not only avoids the simultaneous power outage of transmission lines but can also be applied flexibly to any location. This method enables the power transmission system to accomplish the replacement of old transmission towers with the lowest possible impact.

-

5-2 Introduction to the Tower Wrapping Replacement Method:

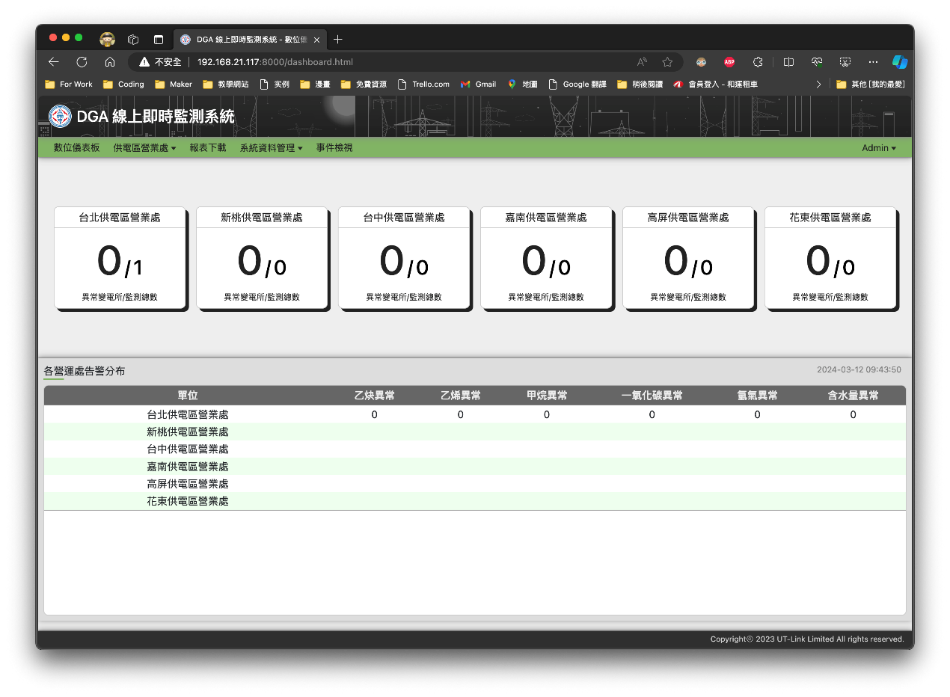

As the name suggests, the tower wrapping replacement method, installs the new tower around the outer side of the old transmission tower and gradually replaces it. The method entails the following steps (also outlined in Figure 1):

-

First, install new tower angle irons on the existing foundation of the old tower. Next, set up the new tower footings on the new angle irons. When power is turned off on the left side of the old tower, the left side of the new tower’s body is installed.

-

When power is restored to the left side of the old tower, power to the right side can be turned off. The right side of the new tower’s body can then be installed. Additionally, power lines can be moved to the right side of the new tower. Once the lines have been shifted, the old cross-arm can be removed from the right-side of the old tower.

-

A new cross-arm can be installed on the right-side of the tower. Wires can then be moved to the new cross arm.

-

When power is restored to the lines on the right-side of the tower, the power can again be cut to the left side of the tower. The lines from the old, left cross-arm can then be moved to the left-side of the tower body. After the lines are shifted, the old cross-arm can be removed from the left-side of the tower.

-

The new cross-arm can then be installed on the tower’s left side and power lines can be moved onto it.

Finally, the body of the old tower can be removed and power can be restored to the left-side of the new tower. This completes the replacement process.

-

-

5-3 Advantages and Prospects:

The greatest advantage of the Tower Wrapping Replacement Method, proposed here, is that it does not involve either simultaneous outages or land acquisition. During the replacement process, power lines on at least one side of the tower can maintain a continuous power supply. These features allow this method to greatly alleviate the above-mentioned difficulties while loosening the time and space constraints on the replacement of old transmission towers, thereby increasing the flexibility of maintenance work

Figure 1 – The Tower Wrapping Replacement Method

-

6-1 Abstract

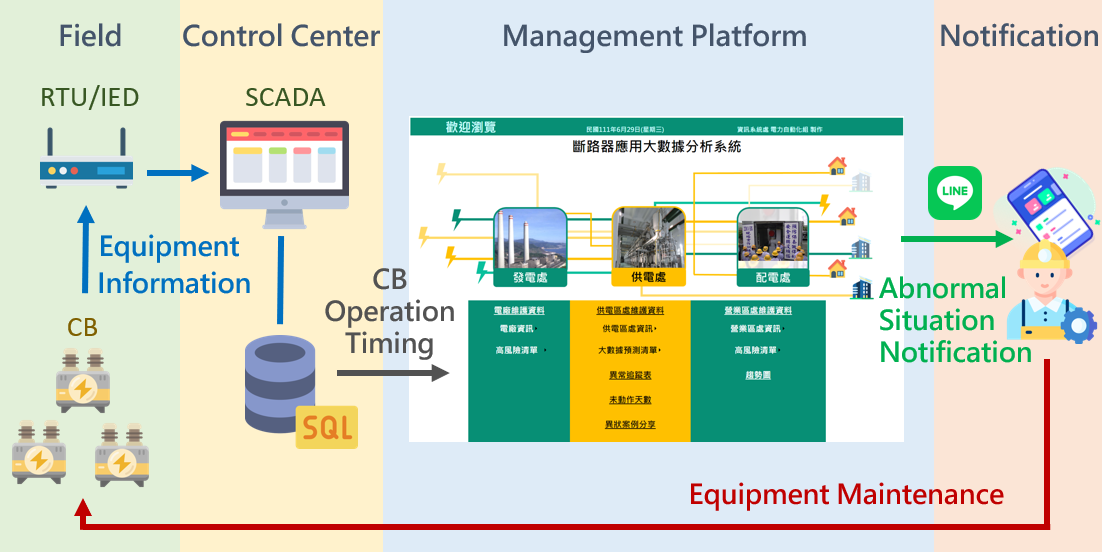

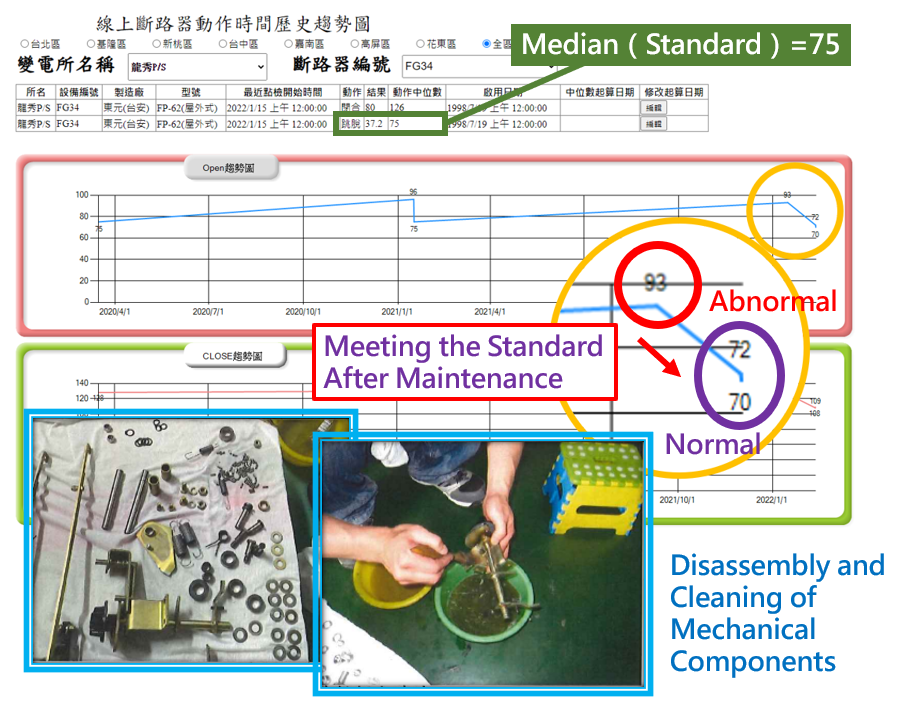

In 2014, Taiwan Power Company (TPC) began using Intelligent Electronic Device (IED) operation information from Remote Terminal Units (RTU) and IEC 61850 substations as trigger signals for calculating the Sequence of Events (SOE) times for auxiliary switches from circuit breakers. An online circuit breaker inquiry system was then established, and more than 830,000 pieces of information have been accumulated so far. In 2018, AI big data analysis was introduced using equipment brand, age of use and past operation timing. This led to the successful diagnosis of 410 abnormal circuit breakers, particularly those with dull or delayed mechanisms. The prediction accuracy rate reached 30%.

In 2021, the median number of the close/open operation timing was used as the diagnostic standard and the construction of IEC61850 standard substations was promoted. This will effectively improve accuracy by 40% and result in the successful diagnosis of 70% more abnormal circuit breakers.

To allow for ongoing status monitoring, a web-based management platform and an notification app were developed (as shown in Figure 1). When a circuit breaker experiences an abnormal operation, the system will immediately notify maintenance personnel so that the issue can be resolved quickly. This greatly improves the security of the power grid.

-

6-2 Big Data Statistical Analysis of Online Circuit Breaker Operation Timing

The operating times for circuit breaker that was obtained through the RTU/IED triggered SOE information technology (see above) varies depending on the sampling circuit and the auxiliary switch of the operating link. According to analysis, performed using the AI big data XGBOOST model, under normal circumstances the close/open operation timing is less than 5ms regardless of whether the circuit breaker is closed or open. Consequently, the median number of the close/open operation timing was introduced in 2021 as the diagnostic standard, allowing for greatly shortened AI big data analysis times.

-

6-3 Construction management platform and practical application results

The large database of circuit breaker operation times was combined with data management functions to build a management platform. This platform allows for the reporting of abnormalities in real-time and issues notifications via app. This quickly alerts maintenance personnel and appraises them of the situation so that maintenance can quickly be arranged in accordance with the problematic equipment’s operational trends, brand, type and use history (see Figure 2). At the time of writing, 223 circuit breakers with institutional exception have been diagnosed and processed.

Figure 1 – The online circuit breaker operation timing management platform and action notification app

Figure 2 – Online circuit breaker operation timing exception handling results

-

7-1 Summary

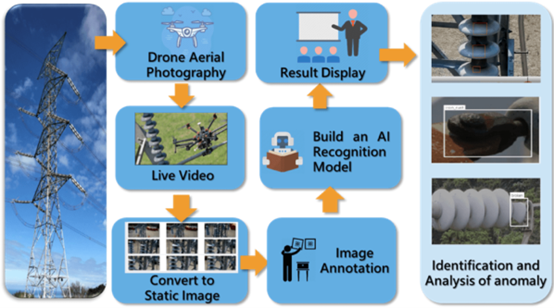

In recent years, with the rapid development of communication technology, the development technology of lightweight and highly maneuverable unmanned remote-controlled aircraft has gradually matured. The power supply department of TaiPower Company has attempted to use drones to assist in inspection work, successfully finding the accident point of the iron tower on the riverbed. With the increasing maturity of drone technology, work projects such as tower base monitoring, line inspection, finding accident points, and iron tower corrosion investigation have also been gradually added. Especially in recent years, extreme weather factors, natural disasters are increasingly frequent. After wind disaster or rainstorm, the road collapse during patrol inspection makes vehicles unable to reach, or the search for line accident points in power transmission depends more on drone assistance. In addition, the main types of occupational hazards in the operation of overhead transmission lines are 'falling' and 'induction'. With the assistance of drone, the occurrence of such disasters can also be reduced, and efforts can be made towards improving the working environment and reducing the occurrence of occupational hazards.

Figure 1: AI Intelligent Inspection

-

7-2 Smart Inspection:

Most of the overhead transmission line towers in Taiwan are located in the middle of high mountains or river basins, and traditional inspections rely heavily on human labor. Currently, TaiPower Company is actively promoting the new technology of drone intelligent inspection AI. Drones are equipped with dual light cameras for line inspections. In addition to inspecting the status of obstacles, iron and ground wires, the camera can switch to infrared mode to detect the temperature of wire connection points. Drone intelligent inspection can improve the visual blind spots limited by terrain and environment, and enhance inspection efficiency.

By using licensed pilots to conduct drone inspections, the captured videos are transmitted back to the backend host system for data processing. Using an AI image recognition system, abnormal conditions such as obstacles, iron objects, grounding wires, and wire junction temperatures are automatically identified, and abnormal reports are generated (as shown in Figure 1). After confirmation and subsequent improvement work by Taipower personnel, the operation and maintenance performance of transmission lines is effectively improved, and the stability and reliability of the power system are enhanced.

-

7-3 Conclusion:

In recent years, due to the rapid development of information, the transmission of information requires speed and accuracy. Traditional manual inspection methods are often limited by factors such as terrain and environment, and their efficiency is slightly insufficient. By assisting transmission line inspections with drones, the efficiency and effectiveness of inspection operations can be comprehensively improved, and the quality of inspections can also be enhanced.

Smart inspection "is the future and ongoing form of transmission line inspection, which establishes a foundation of" soft "strength through complete drone management and operator training. Through the gradual introduction of new technologies, inspection work can be more accurate and reliable, weaknesses can be detected early, and power supply stability can be improved.

-

8-1 Abstract

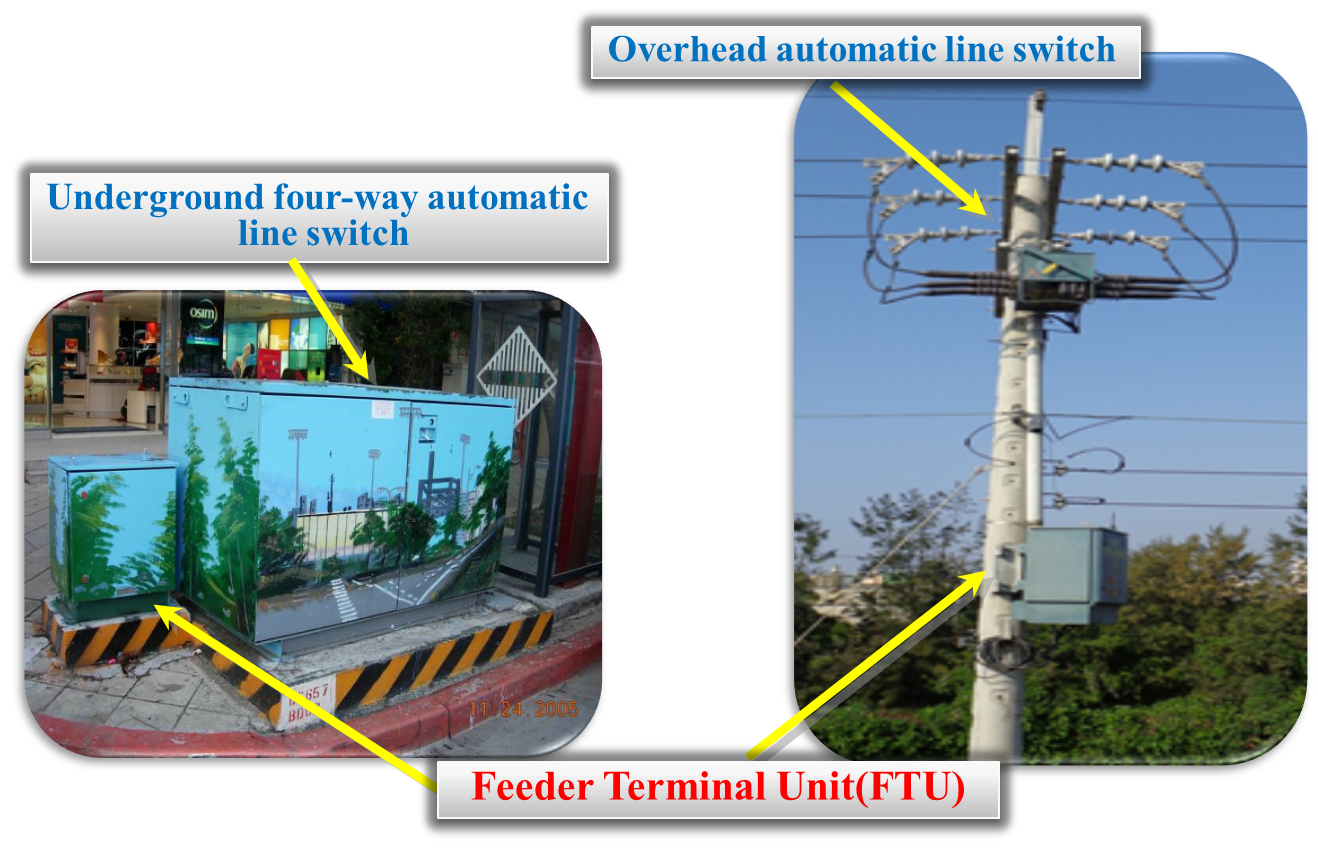

In alignment with the overall smart grid project, we continue to promote feeder automation projects within the distribution system, aiming to gradually incorporate all users into automated feeders. This will further enhance the benefits of distribution automation and improve power supply reliability. The Distribution Department has also continued to strengthen management and conduct rolling reviews of the following aspects.

-

8-2 The Planning and Design

-

Accelerate the deployment of automatic line switches and incorporate monitoring:

Continue to actively deploy and annually review the number of automatic circuit switches being monitored to comprehensively improve the automation rate of distribution feeders nationwide. Full (100%) automation of distribution feeders is expected to be achieved by 2025. It can effectively reduce the scope of accidental power outages, shorten user power outage time, and improve power supply quality by quickly isolating the fault interval and restoring power upstream and downstream through the system.

-

Installation of automatic circuit breakers on divergent small loops:

In addition to deploying automatic circuit switches on distribution feeder trunks, the installation of automatic circuit switches on divergent small loops in metropolitan areas such as Taipei, Taichung, and Kaohsiung is also being implemented and monitored. Based on the automation benefits observed in these metropolitan areas, the deployment will be expanded to further reduce the scope and duration of power outages for divergent lines.

Figure 1. Incorporate automation switches into monitoring

-

Accelerate the deployment of automatic line switches and incorporate monitoring:

-

8-3 Engineering Management

-

Accelerate the completion of bidding announcements:

We require that the branch office responsible for the annual feeder automation project complete the bidding announcement before the end of the previous year and include the timing of the bidding announcement as a scoring item in the operational performance index of each branch business office.

-

Regularly update the progress of management and control tracking:

The branch office regularly submits reports such as the ‘Bi-weekly Management Report before Signing the Contract,’ the ‘Monthly Report on Construction and Management of Distribution Feeder Automation Engineering,’ and the ‘Monthly Report on Implementation of Control and Management of Distribution Feeder Automation Project’ to facilitate tracking and management.

-

Continue tracking and controlling cooperative projects:

If coordination projects or pre-operations are hindered or delayed, a coordination meeting or other measures will be implemented to notify relevant departments and provide necessary assistance.

-

Accelerate the completion of bidding announcements:

-

8-4 Conclusion

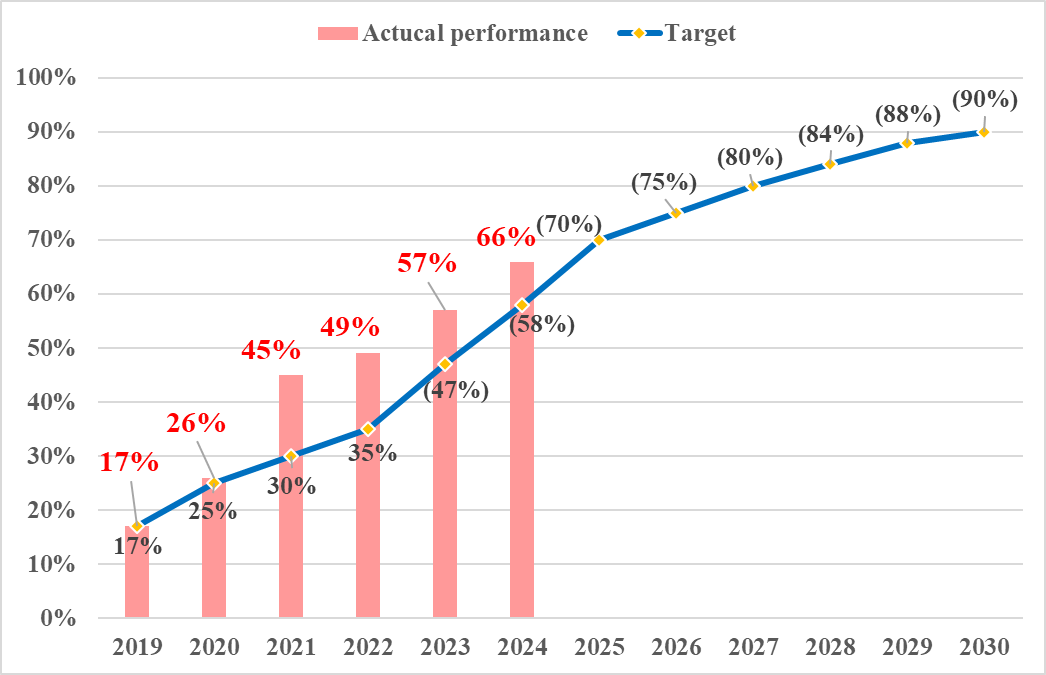

As of 2024, the Distribution Department has deployed 9,784 automated feeders, accounting for 96% of the total feeders. In 2024, the proportion of accidents with downstream power restoration within 5 minutes reached 66%, significantly accelerating accident recovery time.

Figure 2. Proportion of Accidents with Downstream Power Restoration within 5 Minutes

Compared to traditional field operations, 110,167 automatic line switch operations have been performed remotely, saving 36,722 hours of manual operation time and reducing the need for personnel to operate equipment on-site. Furthermore, this enhances workplace safety.

-

9-1 Abstract

With the changes of the times, the living standards of the people are improving, and the customers are increasingly demanding the quality of the services provided by Taipower company. In order to effectively reduce the time of power outages and improve the reliability of power supply, the department of Distribution has reviewed and continued the following aspects:

-

Actual Action

-

9-2-1 The Planning and Design

-

Planning and designing the power distribution line system as a loop-type method, and adding switches to isolate and change power transmission way that reduce the scope of power outages when the construction or maintenance operations are proceeded in the future

-

Before designing a case, the designers consider the factors, such as the site environment and the conditions of the power distribution line equipment, to plan the optimal design to reduce the construction projects with power outage (e.g., live line operations or high-voltage parallel transfer operations).

-

-

9-2-2 The Construction

-

Before the construction of the project, we review the methods of the case and prioritize the work without power outages, and send personnel to survey the site in advance to check whether the information about the relevant equipment is correct or not that eliminates all factors that affect the construction, and plan a suitable work schedule to shorten working hours and reduce the area of impacted users.

-

Before arranging the power outages works, review and address the cases with the same power outage scopes and implement controlling them to reduce the number of power failure. In addition, according to the content of the case, properly plan the operation process and deploy appropriate constructers and equipment to complete within the planned time.

-

-

9-2-3 The Technique

-

Continue referring to the foreign construction technologies and improve various construction methods, and gradually promote non-blackout construction operations to reduce the time and the number of power outages works under the premise of ensuring safety at work.

-

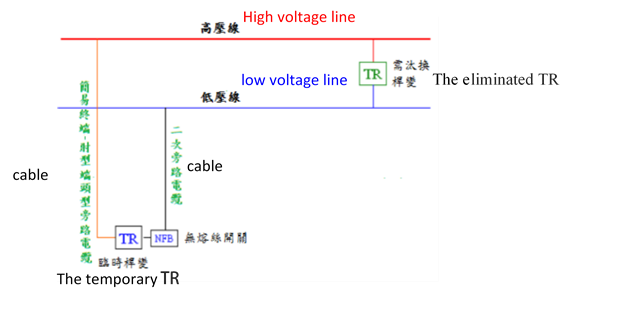

The construction projects that have been implemented without power outages include "live line operations", "high-voltage parallel transfer operations" and "temporary transformer operations". The construction department can choose the appropriate operation way according to the content of the case and considering the site environment and system to reduce the time and number of power outages.

Figure 1. temporary transformer operations

-

-

9-2-4 The Distribution lines

-

Covering the overhead bare lines:

Since 1999, the overhead bare aluminum wires have been gradually replaced with cross-linked PE covered wires, and the equipment such as terminal cable clamps and wiring rings have been continuously developed to reduce the chance of overhead lines being touched by something and effectively prevent people from touching high-voltage lines.

Figure 2. Covered terminal cable clamps

Figure 3. Covered wiring rings

-

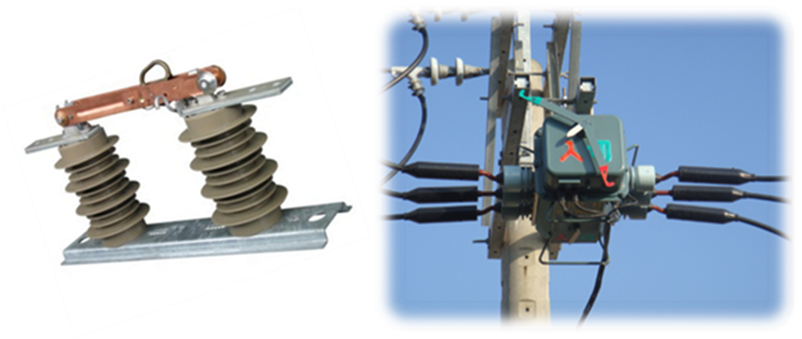

Covering the line switches:

The single-phase switches are all exposed, which easily lead to feeder tripping caused by something likes birds, beasts, trees, etc. Therefore, the three-phase connected dynamic load on-off switch has been developed to completely cover the charged parts.

Figure 4. single-phase switches (left one) and the three-phase connected dynamic load on-off switch (right one)

-

Improved exposed weaknesses in overhead equipment:

In order to reduce the damage of overhead lines caused by wind disasters and the contact of birds, animals and trees, etc., we gradually develop the equipment to improve the exposed parts of transformers and power fuses, and pursue the full-covered the power distribution lines in the future.

-

Covering the overhead bare lines:

-

9-2-1 The Planning and Design

-

9-3 Conclusion

In summary, the improvement measures implemented by Taipower will effectively reduce power blackout time.

-

10-1 Causes of Incidents

Causes of Incidents

- 1. Birds Nesting.

- 2. Birds Droppings.

- 3. Insufficient Insulation Distance.

- 4. Bird Contact with Live Equipment.

- 5. Formosan Masked Palm Civet Climbing.

-

10-2 Improvement Strategies

Improvement Strategies

- 1. Install bird deterrent devices on steel structures within the substation.

- 2. Fill potential bird roosting areas with materials such as foam, rubber, or stainless-steel sheets.

- 3. Conduct regular inspections for bird nests and nesting materials, with increased inspection frequency during peak nesting seasons.

- 4. Enhance nighttime patrols by on-site security personnel and increase patrol frequency.

- 5. Trim surrounding trees to minimize potential access routes into the substation.

- 6. Set animal traps at known entry points and replace straight barbed wire with coiled barbed wire.

-

7. Install motion sensor lights to deter animals from approaching energized equipment.

- 10-3Improvement Measures

Improvement Measures

-

Short-Term

We have promoted turf improvement in substation switchyards and laid gravel to reduce the availability of bird nesting materials. In addition, we have enhanced patrols around the substation and removed potential nesting materials such as vines and wires. A total of 20 improvement projects for outdoor substations within the power supply system have been identified—11 have been completed, while the remaining projects are currently under construction.

-

Long-Term

We are continuing to promote the substation reconstruction plan, aiming to convert aging or outdoor substations into indoor substations.

- ✔ In 2019, 9 reconstruction proposals were submitted to the Executive Yuan for approval.

- ✔ An additional 15 proposals were submitted in 2023, bringing the total number of reconstructions plans to 24.

-